Industrial Degreasing Equipment

Price 850000.00 INR/ Unit

Industrial Degreasing Equipment Specification

- Pressure Ratings

- 8-12 Bar

- Water Flow Rate

- 18-28 L/min

- Tank Capacity

- 150 Liters

- Connectivity Type

- Wired

- Equipment Type

- Automatic Degreasing Machine

- Power Source

- Electrical

- Accessories

- Nozzle Set, Hose, Brush Set

- Features

- Corrosion Resistant, Heavy Duty, Easy Maintenance

- Suction Power

- 2500 W

- Control System

- PLC Controlled

- Brush Types

- Rotary, Fixed

- Material

- Stainless Steel

- Type

- Industrial Degreaser

- Condition

- New

- Fuel Type

- Electric

- Use

- Industrial Cleaning, Machinery Maintenance

- Cleaning Process

- Degreasing

- Cleaning Type

- High-Pressure Cleaning

- Capacity

- 100-500 Liters (Customizable)

- Voltage

- 220-240 V

Industrial Degreasing Equipment Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5 Units, , Per Month

- Delivery Time

- 20-30 Days

About Industrial Degreasing Equipment

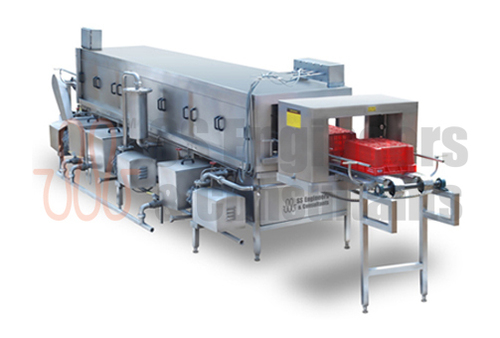

Industrial Degreasing Equipment

SS Engineers are one of the most Dynamic Professionals in Design and Manufacture of Industrial Components Washing Machine suitable for complete Stainless Steel / Aluminum Industrial ware products, the machine includes Pre-wash, Detergent wash, Hot water wash Air blowing, Hot Air Drying & Air cooling sections. SS Engineers are experts in the manufacture of industrial washing systems suitable for Mass, Medium and Small companies.

Superior Cleaning Performance

With a configurable capacity of 100-500 liters and a powerful 2500 W suction, this equipment tackles the toughest grease and grime. The rotary and fixed brushes, combined with high-pressure operation, ensure thorough cleaning of machinery components. Its PLC-controlled processes and digital interface simplify operation for both automatic and semi-automatic cycles.

Built for Industrial Environments

Constructed entirely from corrosion-resistant stainless steel, this degreasing machine endures demanding factory conditions. Safety features such as emergency stop and overheat protection enhance operational security. Its floor-standing design and industrial grey color suit a variety of industrial workspaces.

Efficiency and Compliance

Operating at a noise level below 65 dB and with RoHS environmental compliance, this degreaser meets modern workplace standards. Supporting both water-based and solvent-based degreasers, it reduces environmental impact while maintaining superior cleaning performance. Flexible customization accommodates operational needs.

FAQ's of Industrial Degreasing Equipment:

Q: How does the automatic degreasing machine operate and what processes does it support?

A: The equipment functions using PLC-controlled cycles and offers both semi-automatic and automatic modes. It supports high-pressure cleaning with water-based or solvent-based degreasers, efficiently removing oil, grease, and dirt from industrial components.Q: What are the dimensions and installation requirements for this degreasing machine?

A: The machine measures 1550mm x 800mm x 1200mm and is designed for floor-standing installation. It requires a standard electrical power supply (220-240 V) and can be set up in industrial workshops, machinery plants, or maintenance facilities.Q: When should I use this equipment for optimal results?

A: It is recommended for routine or scheduled industrial cleaning and machinery maintenance to prevent residue buildup. Each batch cycle lasts between 15 and 30 minutes, enabling timely and thorough degreasing.Q: Where is this degreasing machine most effectively used?

A: This equipment is ideal for manufacturing plants, automotive workshops, heavy machinery maintenance facilities, and other industrial settings that demand powerful, efficient degreasing.Q: What safety and environmental features does the machine offer?

A: The degreaser is equipped with an emergency stop button and overheat protection. It is RoHS compliant, ensuring minimal environmental impact, and is constructed from corrosion-resistant stainless steel for durability.Q: How does the user interface enhance operation and maintenance?

A: A digital panel display provides straightforward controls, process monitoring, and error alerts, making it easy to operate and maintain. Maintenance is further simplified by the heavy-duty build and accessible components.Q: What are the benefits of using this industrial degreasing equipment?

A: Benefits include efficient and thorough cleaning, reduced manual labor through automated cycles, customizable capacity, reduced downtime due to quick batch processing, energy efficiency, and compliance with safety and environmental standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Washing Equipments Category

Industrial Component Washer Machine

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220415 V AC

Capacity : 50500 Liters (Modeldependent)

Type : Other, Industrial Component Washer Machine

Cleaning Type : Other, Automatic

Industrial Crate Washer

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Voltage : 415V, 3 Phase, 50 Hz

Capacity : 200500 Crates per Hour

Type : Other, Automatic Industrial Crate Washer

Cleaning Type : Other, Industrial Cleaning

Marine Crate washer Machine

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 380415 V, 3 phase

Capacity : Up to 200400 crates/hour

Type : Other, Automatic Cleaning Machine

Cleaning Type : Other, Hot & Cold Water Cleaning

Cylinder Washer

Price 850000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220240 V

Capacity : Varies by Model (typically 16 cylinders per cycle)

Type : Other, Cylinder Washer

Cleaning Type : Other, High Pressure Wash

Send Inquiry

Send Inquiry