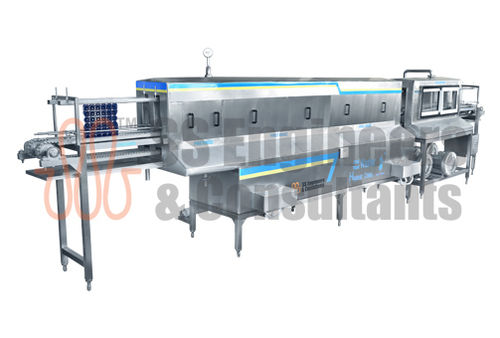

Industrial Bottle Sterilzerr

Price 850000.00 INR/ Unit

Industrial Bottle Sterilzerr Specification

- Equipment Type

- Bottle Sterilization Equipment

- Control System

- PLC-based automatic control

- Water Flow Rate

- Variable, adjustable per process requirement

- Connectivity Type

- Panel operated/local interface

- Tank Capacity

- 100-400 L (varies by model)

- Pressure Ratings

- 1.5 2.5 bar

- Features

- Stainless steel body, safety interlocks, digital temperature display, high efficiency, temperature & pressure control

- Accessories

- Bottle baskets, drain valve, safety valve, pressure gauge

- Power Source

- Electric Powered

- Material

- Stainless Steel

- Type

- Industrial Bottle Sterilizer

- Condition

- New

- Fuel Type

- Electric

- Use

- Sterilizing bottles in industrial applications

- Cleaning Process

- High-temperature steam sterilization

- Cleaning Type

- Automatic

- Capacity

- Up to 1000 bottles/hour

- Voltage

- 220-380 V

Industrial Bottle Sterilzerr Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5 Units, , Per Month

- Delivery Time

- 20-30 Days

About Industrial Bottle Sterilzerr

Industrial Bottle Sterilzerr

SS Engineers Bottle Sterilizers is heavy duty process machines primarily used to process milk filled glass bottles. SS Engineers manufactures full range of bottle Sterilizer's (steam retort) from 150 bottles to 2880 bottles per batch. All retorts can be ordered in lengths from 1 basket to 8 baskets capacity. Customer options: includes automatic or manually-opened door designs. We offer orbit type door opening & closing. The customer may also specify MS. or SS construction. Uses: In dairy industries for sterilization of flavored milk bottles.

We offer orbit type door opening & closing. The customer may also specify MS. or SS construction. Uses: In dairy industries for sterilization of flavored milk bottles.

Features: Excellent bottle sterilizing capacity, Compact design, less power consumption.

Tags: Bottle Sterilizers, Sterilized Retort, retort, Water spray, Over pressure Retort, Steam Retort, Turn Key Line, Rotary Retort, Compact Retort, Pre-cooker, Canned Food, Milk Bottle Sterilizers, Complete Processing Plant for Sterilized Milk, Fruit Juice, Yogurt, Water Spray Retort, Sterilizers, Autoclave, Food & Beverage Industry, Fully Automatic Stainless Steel Flavored Milk Bottle Sterilizers, retort bottles, bottle retort, retort bottle filling machine, retort pp bottle, glass bottle retort, reportable glass bottles, retort, retort pouch, retort stand, canning retort, retort machine, retort furnace, food sterilizing autoclave, food sterilizer, ozone food and water sterilizer, food sterilizing autoclave, food sterilizing machine, food steam sterilizer, food sterilizer, sterilized food, sterilized can food, food industry sterilizer, uv sterilizers for food, bottle sterilizer, baby bottle sterilizer, milk bottle sterilizer, bottle sterilizer, baby feeding bottle sterilizer, glass bottle sterilizer, sterilized bottles, flavored milk bottle sterilizer, bottle sterilizer machine, industrial bottle sterilizer, steam sterilizer, autoclave steam sterilizer, high pressure steam sterilizer, steam sterilizer, horizontal steam sterilizers, steam sterilizer machine, horizontal cylindrical steam sterilizer, cylindrical steam sterilizer, vertical steam sterilizer, steam sterilizer autoclave.

Superior Sterilization Efficiency

With high-temperature steam capable of reaching 135C and cycle times as short as 10 minutes, this sterilizer ensures rapid and thorough bottle sanitation. Automatic controls and digital displays streamline operation while a corrosion-resistant body guarantees durability for industrial use.

Flexible Design for Diverse Applications

Engineered for food, pharmaceutical, and beverage industries, this sterilizer offers customizable chamber sizes and is suitable for various bottle types and capacities. Its floor-mounted, skid-based layout ensures easy installation and seamless integration into existing production lines.

Intelligent Safety and Control

The sterilizer boasts essential safety features including automatic shutoff, overheat protection, safety interlocks, and a PLC-based control system. A digital temperature display provides real-time monitoring, enhancing both operator safety and product quality.

FAQ's of Industrial Bottle Sterilzerr:

Q: How does the Industrial Bottle Sterilizer ensure complete sterilization?

A: It employs high-temperature steam (up to 135C) to eradicate bacteria and contaminants. The sterilization cycle is automatic and fully adjustable, ensuring each batch receives consistent, comprehensive treatment for optimum hygiene.Q: What types of bottles and industries is this sterilizer suitable for?

A: This equipment is ideal for sterilizing bottles used in the food, beverage, and pharmaceutical sectors. Its customizable chamber sizes cater to a wide range of bottle shapes and production requirements.Q: When is the best time to perform sterilization cycles using this equipment?

A: Sterilization should be performed in accordance with your production schedule, typically before filling or packaging bottles, to maintain the highest sanitation standards and ensure product safety.Q: Where should the Industrial Bottle Sterilizer be installed?

A: The sterilizer features a floor-mounted, skid-based design, making it suitable for installation in dedicated production spaces within industrial facilities. Adequate ventilation and access to water and power connections are recommended.Q: What is the sterilization process used by this machine?

A: The unit uses an automatic, high-temperature steam sterilization process. Bottles are loaded into specialized baskets, and the control system manages temperature, pressure, and cycle duration for precise, hands-free cleaning.Q: What are the main benefits of using this sterilizer in industrial applications?

A: Key benefits include rapid cycle times, adjustable settings to meet specific requirements, reliable safety features, and a polished stainless steel exterior for easy cleaning and long-term resistance to corrosion.Q: How does the operator control and monitor the sterilizer's operation?

A: A PLC-based control interface and local operating panel allow users to set parameters, monitor cycles, and view real-time data, while integrated safety interlocks and alarms ensure secure, trouble-free operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Washing Equipments Category

Dairy Crate Washer

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Cleaning Process : Other, High Pressure Water Jet

Fuel Type : Electric

Capacity : 300500 crates/hour

Condition : New

Tray Washing Machine

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Cleaning Process : Other, High Pressure Jet Spray and Soaking

Fuel Type : Electric

Capacity : 100500 Trays/Hour (Customizable)

Condition : New

Basket Washer

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Cleaning Process : Other, High Pressure Spray and Rotational Cleaning

Fuel Type : Electric

Capacity : Up to 50 Baskets per Cycle

Condition : New

Egg Washer

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Cleaning Process : Other, Water Spray and Rotary Brushing

Fuel Type : Electric

Capacity : 36005400 eggs/hour

Condition : New

Send Inquiry

Send Inquiry