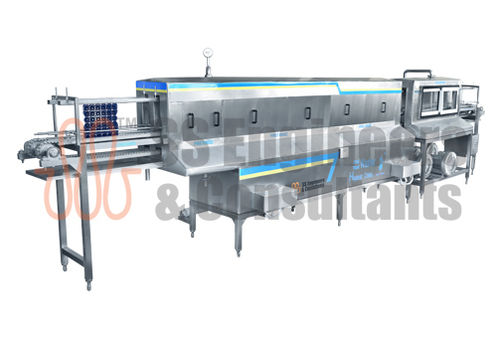

Egg Tray Washing Equipment

Price 850000.00 INR/ Unit

Egg Tray Washing Equipment Specification

- Connectivity Type

- Fixed Installation

- Water Flow Rate

- 50-100 L/min

- Suction Power

- High

- Tank Capacity

- 200-500 Liters

- Power Source

- Electric Motor

- Control System

- PLC Control Panel

- Equipment Type

- Tray Washing Machine

- Pressure Ratings

- 3-6 bar

- Accessories

- Spare Brushes, Water Hoses, Instruction Manual

- Features

- Automatic Operation, Corrosion-resistant, Easy to Operate

- Brush Types

- Rotary Nylon Brushes

- Material

- Stainless Steel

- Type

- Automatic

- Condition

- New

- Fuel Type

- Electric

- Use

- Commercial Egg Tray Cleaning

- Cleaning Process

- High-Pressure Water Spray

- Cleaning Type

- Industrial Cleaning

- Capacity

- 1000-5000 trays/hour

- Voltage

- 220-380 V

Egg Tray Washing Equipment Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units, , Per Month

- Delivery Time

- 20-30 Days

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Middle East, Central America, South America, Asia, Africa

About Egg Tray Washing Equipment

Egg Tray washing Equipment Washer

SS Engineers & Consultants Egg Tray Washing Machine for washing Commercial Egg Trays, the trays used in the egg processing industry can become extremely dirty and often stick to one another, as well as being designed and constructed specifically to customer requirements to increase efficiency and productivity. Designed and certified to eliminate any bacteria, even the most aggressive, they offer impeccable results in terms of hygiene, reaching extremely high standards like those of the pharmaceutical/hospital

Product details

| Minimum Order Quantity | 1 Unit |

| Washing Type | HIGH SPEED JET WATER SPRAY |

| Model Number | SSEC/ETW002 |

| Max Temperature | 60 C |

| Loading Type | Front Loading |

| Design | CUSTOMIZED |

| Color | STAINLESS STEEL |

| Automation Grade | Automatic |

| Surface Treatment | Galvanized |

| Customized | Yes |

| Brand | Ss Engineers And Consultants |

High-Efficiency Cleaning Performance

Designed with industrial-grade components, the machine cleans 1000 to 5000 trays per hour using high-pressure water jets and rotary nylon brushes. Its PLC-controlled automation ensures consistent results and effortless operation, minimizing manual intervention.

Eco-Friendly Water Management

The built-in water recycle tank and automatic drainage system reduce overall water consumption. This integrated approach supports sustainability and operational savings, making it ideal for facilities with high environmental standards.

Safety and Reliability

Featuring overload protection and an emergency stop switch, the equipment prioritizes operator safety. Its stainless steel body ensures resistance to corrosion, maintaining a hygienic and durable workspace for years of continuous use.

FAQ's of Egg Tray Washing Equipment:

Q: How does the automatic egg tray washing process work?

A: The machine uses a combination of high-pressure water spray and rotary nylon brushes to effectively remove contaminants from egg trays. Trays are automatically loaded, washed, rinsed, and dried, all controlled by a user-friendly PLC control panel.Q: What types of facilities benefit most from this equipment?

A: Poultry farms, commercial hatcheries, and food processing plants especially benefit from this industrial egg tray washing equipment, as it is engineered for high-volume, hygienic cleaning needs.Q: When should the egg tray washer be operated for optimal results?

A: Operate the machine during scheduled cleaning cycles or after every use of the trays to maintain hygiene standards. Its robust build allows for frequent, daily operation without loss of performance.Q: Where should the tray washing machine be installed?

A: It is designed for floor-mounted installation in dedicated cleaning areas within commercial or industrial settings. Fixed connectivity and easy drainage make it suitable for large-scale operations.Q: What is the benefit of the integrated water recycling system?

A: The integrated recycle tank minimizes fresh water usage by filtering and reusing water within the system, reducing both operational costs and environmental impact.Q: How easy is it to operate and maintain the equipment?

A: The machine features an intuitive PLC control panel and comes with an instruction manual. Routine maintenance involves checking the brushes (spare included), inspecting hoses, and ensuring the drainage system is clear.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Washing Equipments Category

Inclined Crate Washing Machine

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220240V

Cleaning Type : Other, Automatic

Use : Other, Industrial/Commercial crate cleaning

Fuel Type : Electric

Degreasing Machine

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220240 V

Cleaning Type : Other, Automatic

Use : Other, Surface Cleaning, Industrial Components Degreasing

Fuel Type : Electric

Bin Cleaning Machine

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220240 V

Cleaning Type : Other, Automatic

Use : Other, Industrial Bin Cleaning

Fuel Type : Electric

Dairy Crate Washer

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 380415 V

Cleaning Type : Other, Industrial Cleaning

Use : Other, Dairy Industry, Crate Cleaning

Fuel Type : Electric

Send Inquiry

Send Inquiry