Dairy Plant and Machinery

Dairy Plant and Machinery Specification

- Product Type

- Dairy Plant Machinery

- General Use

- Milk Processing, Pasteurization, Packaging

- Material

- Stainless Steel (Grade 304/316)

- Type

- Automatic / Semi-Automatic

- Capacity

- 500 - 5000 Liters/Hour

- Weight (kg)

- Varies by Model (approx. 800 - 2500 kg)

- Computerized

- Yes

- Automatic

- Fully Automatic

- Control System

- PLC/SCADA Controlled

- Processing Pressure

- 0.2 to 1.5 MPa

- Cleaning System

- CIP (Clean-In-Place)

- Cooling Mode

- Chiller Integrated

- Sterilization Method

- Steam/Hot Water

- Motor Power

- 2 HP - 10 HP (Depending on Size)

- Voltage

- 220/380 V, 50/60 Hz

- Dimension (L*W*H)

- Customized (Common: 3000 x 1500 x 2200 mm)

- Feature

- Energy Efficient, Low Maintenance, High Productivity

- Color

- Silver

- Packing Material Compatibility

- Poly Pack, Bottle, Carton

- Noise Level

- Less than 70 dB

- Installation

- On-Site Service Provided

- Internal Pipe Fittings

- Tri-Clamp SS Fittings

- Safety Features

- Emergency Stop, Overload Protection, SS Guards

- Cooling Efficiency

- Rapid Cooling (Down to 4°C within Minutes)

- Footprint

- Space Saving Modular Design

- Homogenizer Integration

- Available

- Finish Type

- Mirror Finish & Matte Available

- Sanitary Certification

- ISO 9001:2015, CE, GMP

- Filter Type

- Micro & Macro Filtration

- Temperature Control

- Digital Controller (0°C to 95°C)

- Filling System

- Automatic/Manual Options

Dairy Plant and Machinery Trade Information

- Minimum Order Quantity

- 1 Unit

- Main Export Market(s)

- Western Europe, Central America, Eastern Europe, Middle East, South America, Asia, North America, Australia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO90002015

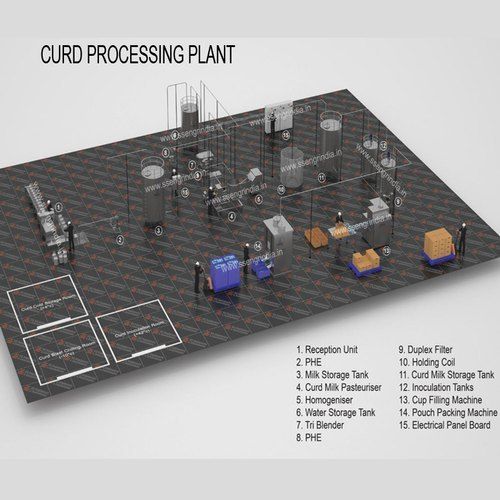

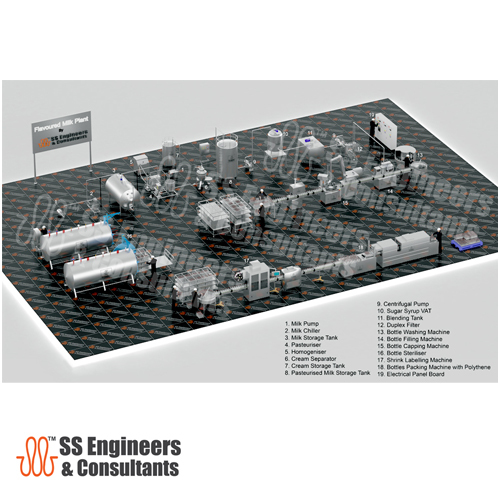

About Dairy Plant and Machinery

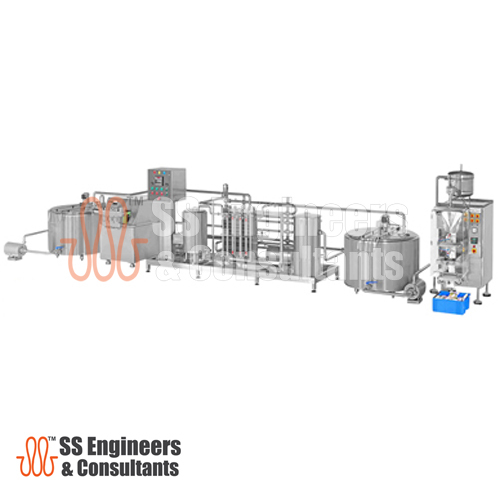

SS Engineers & consultants are a leading supplier of food processing equipment and solutions. When planning a new processing line in an existing Plant or putting up a new production building we can engineer and advise the layout to achieve the best and most productive solution where the best products are produced. We can also plan where and how to make the milk-reception, pasteurizing-facility, filling/packing rooms, incubation, fermentation and cold-stores, where to install Generators, Compressors, Boilers etc.Product details

| Minimum Order Quantity | 1 Plant |

| Usage/Application | Milk |

| Capacity | 2500 litres/hr |

| Material | SS |

| Automation Grade | Automatic |

| Design Type | Customized,Standard |

| Equipment Type | Homogenizer |

| Machine Body Material | SS304 |

https://www.ssengrindia.com/milk-reception-plant.html

Efficient Temperature Management

Our dairy machinery utilizes a digital temperature controller allowing precise regulation between 0C and 95C. This enables accurate pasteurization and keeps product quality consistent. The integrated chiller rapidly cools milk to 4C within minutes, maximizing freshness and safety during processing.

Integrated Homogenizer & Filtration Systems

Homogenizer integration guarantees thorough mixing for superior texture in dairy products. Our micro and macro filtration systems, equipped with tri-clamp stainless steel fittings, ensure hygienic processing and compliance with stringent sanitary standards. The CIP cleaning system further supports a safe and sanitary operation.

Flexible Filling and Packaging Options

Choose between advanced automatic or manual filling systems to match your dairy workflow. The machinery handles poly packs, bottles, and cartons, allowing flexibility to cater to diverse market demands. Installation is hassle-free with onsite service, and the modular design accommodates various space constraints.

FAQ's of Dairy Plant and Machinery:

Q: How does the digital temperature controller enhance dairy processing efficiency?

A: The digital temperature controller maintains accurate temperatures from 0C to 95C, critical for pasteurizing and processing milk. This precision helps ensure product safety, consistent quality, and energy savings during operation.Q: What are the benefits of having homogenizer integration in this machinery?

A: A built-in homogenizer provides uniform mixing, which improves texture and taste of dairy products. It supports stable product composition and enables high-quality milk and cream production, making it ideal for diverse dairy applications.Q: When is it suitable to use the automatic versus manual filling system?

A: Automatic filling is best for higher throughput and standardized packaging needs, while manual filling offers flexibility for specialty products or smaller batch sizes. The system allows switching between modes based on production volume and product type.Q: Where can the dairy plant be installed, and is site installation support available?

A: Our plant is designed for installation in dairy facilities across India, and we provide on-site installation and service support to ensure proper setup and operation. The customizable footprint enables easy integration into various spaces.Q: What process steps does the CIP cleaning system automate?

A: The CIP (Clean-In-Place) system automates internal cleaning using sanitary tri-clamp stainless steel fittings, reducing downtime and ensuring hygiene without manual intervention. This promotes safety and meets ISO 9001:2015, CE, and GMP standards.Q: How does modular design benefit dairy plant operators?

A: The space-saving modular design enables operators to optimize facility layouts, accommodating restricted or unusual spaces. It also allows for future expansion and easy maintenance, enhancing overall operational efficiency.Q: What usage and packing material options are supported?

A: This machinery supports poly pack, bottle, and carton packaging, offering flexibility for various marketing requirements. It streamlines milk processing, pasteurizing, and packing to meet retailer and consumer expectations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dairy Plant & Machinery Category

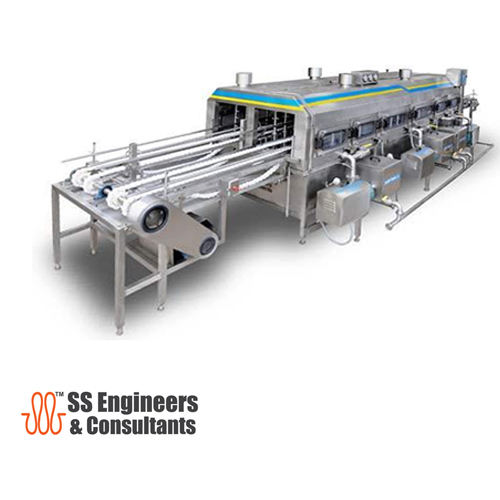

Industrial Crate Washer Machine

Price 900000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Warranty : 1YEAR

General Use : WASHING INDUSTRIAL CRATE

Material : Stainless Steel

crate-washer machine

Price 900000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Warranty : 1YEAR

General Use : WASHING INDUSTRIAL CRATE

Material : Stainless Steel

Ageing Vat

Price 1500000.00 INR

Minimum Order Quantity : 1 Unit

Computerized : Other, Optional

Warranty : 1 Year

General Use : Food and Beverage Industry

Material : Stainless Steel

Milk Reception Conveyor Can Tipping

Price 1500000.00 INR

Minimum Order Quantity : 1 Unit

Computerized : No

Warranty : 1 year

General Use : Milk handling and processing

Material : Stainless Steel

Send Inquiry

Send Inquiry